How Did 3D Printing Begin?

A 3D printer is similar to a normal printer, however a normal printer produces ink on paper. 3D printers, on the other hand, layer atoms on top of each other to create, or print, actual 3D objects.

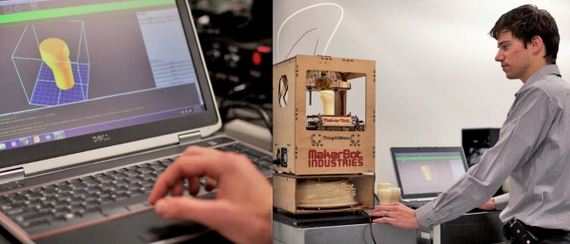

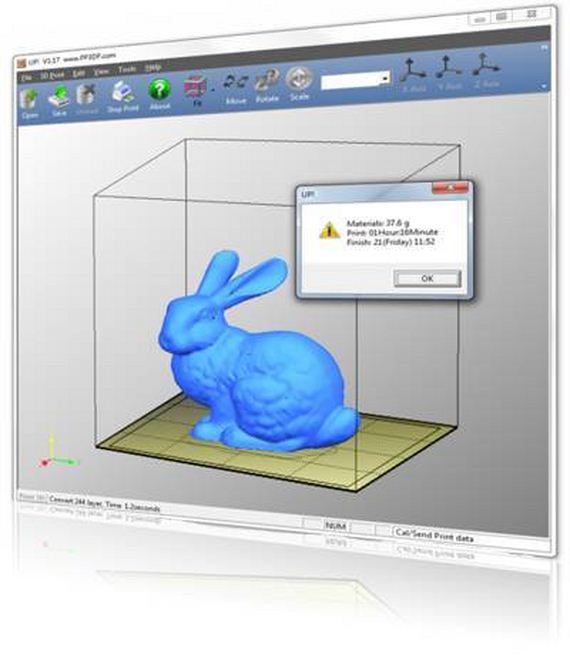

It sounds fascinating, right? But 3D printing is certainly an invention that did not occur overnight. What is known as 3D printing now was once known as rapid prototyping. Rapid prototyping has been in use for many years now, and it involves an engineer designing an object as a computerized aided design file, or CAD. This file would then be sent to machines, which would produce the 3D object.

The only problem with this early type of 3D printing is that the plastics and the metals that were used were just not of a high-enough quality to be used as anything other than a prototype. Although the machine could produce the parts designed, the end product didn’t have structural integrity and was only used to design things that engineers wanted to see a life-size model of.

3D Printing Now

The revolution from previous 3D printing methods to what has been developed today, all began when companies like 3D Systems started designing “radically new materials”. The industry evolved from using weak, waxy plastics to very robust materials that can actually be used as a machine part, rather than just a prototype of a part.

Companies came up with new materials such as nanocomposites, different blends of plastics, and different blends of powdered metals. These materials are able to mimic other stronger materials such as steel. Companies have already began using 3D printers to create parts on demand. For example, Jaguar is already using the technology for rapid product development. Other companies such as the Bell Helicopter division of Textron are also making use of the new technology and its faster production times.

Just think of all the various ways that 3D printing can change our world and the speed in which objects are created! So, what exactly will 3D printers be used for, we hear you ask?

The Dental Industry

That’s right, the dental industry is one industry that is making use of the revolutionary 3D printer. Dating back as recent as 5 years ago, if you went to a dentist to get a crown for your teeth, you would have bitten into clay to produce a mould of your teeth. Your dentist would have then made your crown by hand, even going so far as to hand-sand it!

Fast-forward to the present and crowns are now made completely using 3D technology. Gone are the days when you would bite into that terribly tasting clay mould. Now, the dentist simply wands your mouth with the 3M wand and makes a digital file of your mouth. The dentist then teleports the CAD file and has the implant arrive at his office the very next day. Now that definitely takes some of the hard work out of dentistry!

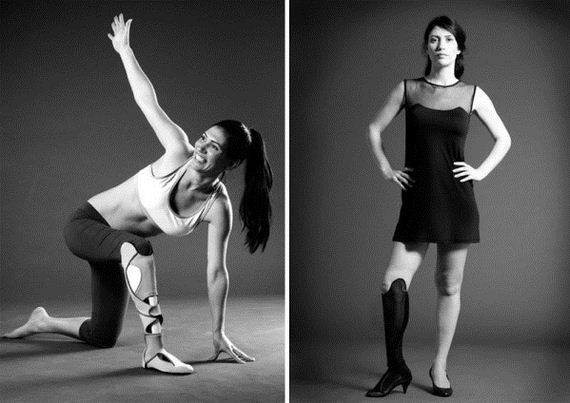

Prosthetic Limbs Or Devices

Many people are praising 3D printing technology because it will have a huge effect on the medical industry. In particular, the creation of prosthetic limbs and devices has now become much quicker and easier. A company in San Francisco called Bespoke Innovations is one company to utilise 3D printing for this very reason.

Gone are the days when prosthetic devices only came in general sizes! Now, companies are able to take a series of different measurements of the individual in order to create custom prostheses that fit comfortably and behave just as the person desires.

This is a remarkable innovation, especially because no two people are the same. Some walk differently, others have more range of movement or flexibility, and everyone has different measurements. Companies can now create a CAD file, from which they can actually print out the limb that is used by the customer.

Point and Click

With the introduction of 3D printing comes the innovation of instant CAD files through laser scanners. A company called FARO Technologies produces a handheld laser that you can point at an object, and the laser will then create a CAD file of what you’re pointing at in real time.

It doesn’t stop there though. This CAD file of the object is then sent to the 3D printer, which will have it printed out in no time. This means that you can basically point your handheld laser at any object you want and reproduce a 3D copy of it for yourself. Amazing, right?!

Of course, as with most new technologies, this method is a concern to personal property, ownership and copyright. Experts have been debating the subject for a long time now, and it’s an issue that isn’t likely to go away.

3D Printing At Home?

That’s correct! It is believed that one day in the future, basically every household will own a 3D printer that they will use on a regular basis for all kinds of needs. Just imagine replacing your paper and ink printers with one of these amazing machines!

Don’t worry, you won’t have to be a millionaire to afford one. Six years ago, 3D printers were selling for a huge sum of $100,000! Fast-forward to the present, and you can now get a fully functional 3D printer for just over a thousand dollars. As expected, over the years this price will continue to decrease, so soon they will become just like buying your average paper-and-ink printer.

So what can one expect to use this printer for at home, you ask? Experts state that individuals and families will soon be using 3D printers to create everything from toys, to curtain rings, to plates and cutlery. We predict that this will save you a lot of trips to the mall!

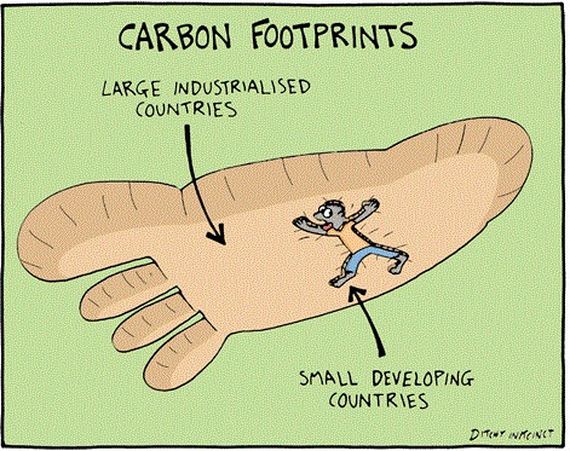

Decreasing Our Carbon Footprint

Lets face it; we cannot deny that we are all leaving a very big carbon footprint on our world. One of the biggest factors contributing to this carbon footprint, however, is the manufacturing, transporting and importing of goods.

So how can 3D printing fix this? Firstly, carbon emissions would reduce a great amount because businesses would no longer need to transport goods. 3D-printed products can be produced and assembled in just one process, therefore hundreds and even thousands of parts would not have to be shipped from dozens of factories around the world.

Another bonus is that companies will no longer have to go in search of space to store their prototypes and other models. This is because most product design files could also be transmitted digitally and then printed on demand from anywhere in the world. This, in turn, will allow more space for environmental conservation.

3D Printing And Space

3D printers are even being developed for space technology! Is there anything they can’t do? NASA has recently contracted a company called Made In Space to develop the first-ever 3D printer for microgravity. Made In Space CEO, Aaron Kemmer states, “The first printers will start by building test items, such as computer component boards, and will then build a broad range of parts, such as tools and science equipment.”

NASA has big plans to use this new technology on not only onboard the International Space Station, but for many other space-related projects. Other companies have also been quick to pick up on the new 3D-printing-in-space craze. Deep Space Industries is considering using 3D printing for harvested asteroid material, the European Space Agency is researching how to print a moon base and Cornell University is actually considering how to print space food. There is a downside however, and this includes the fact that the further away any space station or colony is located, the harder it will be to resupply.

Gun Control And 3D Printing

Defense Distributed, a Texas-based group, announced that it had created the world’s first 3D-printed handgun. As expected, the news sent shock waves throughout America, and a debate for the regulation of printed guns was born. It is undeniable that 3D printers will change our world, however many now worry that the new technology could have extremely negative consequences.

The gun printed by Defense Distributed was created within just 8 months once the group came up with the extreme idea. The printed plastic gun is known as “the Liberator”, and it can be instantly downloaded and printed anonymously by anyone who has access to 3D-printing technology. Recently, The U.S. State Department sent a letter to Defense Distributed demanding it remove the software for 3D-printed guns from its website.

This week, The New York City Council introduced legislation that “would prohibit others than those licensed as gunsmiths from using 3-D printers to make guns and related equipment”. Once a licensed gunsmith creates a gun using a 3D printer, they must then notify the New York Police Department and seek registration within seventy-two hours of completing the printing of the firearm.

Helping Developing Countries

Thankfully, 3D printing means more than just helping the wealthy to become even wealthier. Technology experts have stated that 3D printing can help third world countries who are struggling to obtain everyday items that we take for granted.

If 3D printers can soon be used in our own homes to recreate items of necessity such as plates, cutlery, clothing, etc, then these items can also be recreated to give to those in need. The items can be mass-produced quickly using recycled plastic at a cheap rate, therefore allowing developed countries to help out those dealing with poverty.

Larger 3D printers also exist, such as the Gigabot, and this will allow the new technology to help out even more. Larger 3D printers will be able to create larger items, such as appliances, toilets, baths, boats (as pictured) and more! These products can also be produced at a reduced cost and using recycled plastic. It’s a win-win situation for all involved!

Super Power No More

Experts are also predicting that the rise of 3D printing will have bigger consequences for China. China has become the world’s mass-producing and manufacturing super power, however 3D printing will soon change all of that. Companies will be able to cheaply manufacture their required objects on demand at their own factory. Therefore, they will not be seeking the import of goods from China in order to cut costs.

China will only lose international demand, however, and like every other developed country, supply will be on a local scale. With companies being able to print out their products, the demand for buying overseas will no longer be as important. Everything will soon be produced locally at a much cheaper and quicker rate. The world will certainly change due to 3D printing technology!

Buy Now

Some argue that with the advance of 3D printing, we will soon be saying goodbye to parcels and deliveries. Why is this, you ask? The argument is simple: why click online to “buy now”, when you can instead click to “print now”?

That’s right! Many believe that the days of purchasing goods, such as clothing, accessories, household items, and tools (just to mention a few) will be well and truly over. Instead, people may simply have to pay to print the item they desire. The item, just like a document, would be sent straight to your printer. You will be using a 3D printer, however, so the item will be printed and recreated in front of you within no time. Brings a whole new meaning to the term ‘online shopping’, doesn’t it?

Print An Organ

If someone requires an organ, it could soon become as easy as just printing one! Medical experts are excited for what the future holds when it comes to 3D printing, as it could provide the world with much-needed medical advancements, including helping with organ replacements.

Bio-printing is a term which means “the production of human organs for transplant”. 3D printers can create replacement tissues and organs that are printed layer-by-layer. Incredibly, the parts are made from the organ recipient’s own genetic matter. This allows the new organ or tissue to precisely match the patient’s own body and needs. This also significantly decreases the risk of the patient’s body rejecting their new transplant. Surprisingly, the first commercial 3D bioprinter was developed as early as 2009 by a bioprinting company called Organovo

Print An Organ

If someone requires an organ, it could soon become as easy as just printing one! Medical experts are excited for what the future holds when it comes to 3D printing, as it could provide the world with much-needed medical advancements, including helping with organ replacements.

Bio-printing is a term which means “the production of human organs for transplant”. 3D printers can create replacement tissues and organs that are printed layer-by-layer. Incredibly, the parts are made from the organ recipient’s own genetic matter. This allows the new organ or tissue to precisely match the patient’s own body and needs. This also significantly decreases the risk of the patient’s body rejecting their new transplant. Surprisingly, the first commercial 3D bioprinter was developed as early as 2009 by a bioprinting company called Organovo

Printable Pizza

As mentioned previously, NASA sure are excited about 3D printing technology. So excited in fact, that they’ve invested in a firm that is developing a 3D printer capable of printing pizzas for the International Space Station.

The firm, Systems & Materials Research Cooperation, have already successfully printed an edible block of chocolate! NASA has given the company a $125,000 grant to design a 3D printer capable of taking 30-year shelf stable foodstuffs and making pizza. We bet the astronauts are looking forward to some ‘real’ meals coming their way soon!

This project also has a huge impact on the whole world, however. As you can imagine, if a 3D printer is capable of printing actual food, then could we one day be saying goodbye to supermarkets altogether? Perhaps the Jetson family’s space-age appliance that was capable of producing food on demand wasn’t such a crazy idea after all.

Barnorama All Fun In The Barn

Barnorama All Fun In The Barn